How cans are made

Cans for food, drinks and non-food products may be constructed out of either two or three pieces of metal.

The first cans ever produced were three-piece and they were developed in the middle of the 19th century. They consist of a cylindrical body rolled from a piece of flat metal with a longitudinal seam, usually formed by welding, with a top and bottom, each seamed on the ends of the body.

Three-piece cans may be manufactured in almost any practical combination of height, diameter and shape. This process is particularly suitable for making cans of different sizes as it is relatively simple to change the parameters of the can under production.

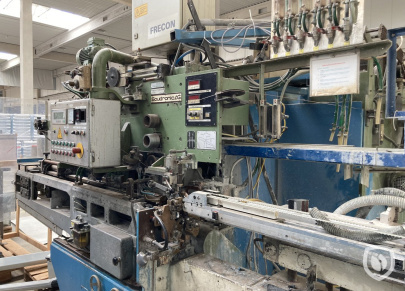

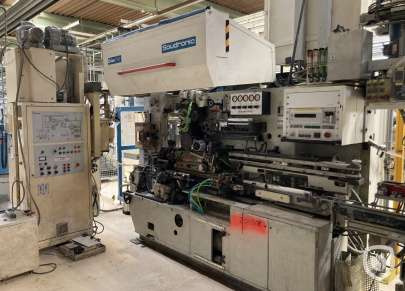

The Cazander Brothers mainly have machinery for three-piece cans in stock.

What is a lacquering unit?

Lacquer is applied to that side of the sheet that will become the internal surface of the finished can. This special lacquer is applied to protect the can itself from corrosion and from any possible interaction between its contents and the metal.

Lacquering the seam weld:

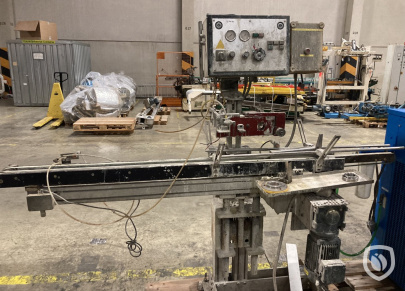

The in- and outside surface of the seam weld is sprayed with lacquer and then cured by blowing heated air onto the in- and outside of the cans.

Cazander Brothers regularly offer quality used Frei and Larsen lacquering units from their extensive stock.